Troubleshooting Common Maintenance Issues for Corrugated Metal Roofs

Managing Condensation in Roof Spaces

Condensation within roof spaces can lead to various issues, including mould growth and deterioration of insulation materials. This often occurs when warm, moist air comes into contact with cooler surfaces, creating droplets of water. Identifying and addressing the sources of moisture is critical. Common culprits include insufficient ventilation or activities within the home like cooking and showering that contribute to humidity.

To effectively manage condensation, ensuring proper ventilation is essential. Installing roof vents or turbine vents can facilitate airflow, helping to maintain a balance between indoor humidity and outdoor air. Additionally, the use of vapour barriers on insulation can prevent moisture from penetrating into the roof space. Regular checks during inspections can help spot any developing issues early, allowing for prompt corrective measures to be undertaken.

Effective Ventilation Solutions

Proper ventilation is essential for preventing condensation build-up in roof spaces, especially in regions with high humidity. Incorporating ridge vents or soffit vents can significantly enhance airflow. These openings allow warm air to escape from the roof space, preventing moisture accumulation and subsequently reducing the risk of corrosion on metal surfaces.

In addition to passive ventilation methods, mechanical ventilation systems can offer additional support. Installation of exhaust fans can effectively remove humid air, improving the overall climate within the roof space. Choosing the right balance between passive and mechanical options ensures optimal ventilation, which is crucial for the longevity of corrugated metal roofs.

Cleaning and Maintenance Practices

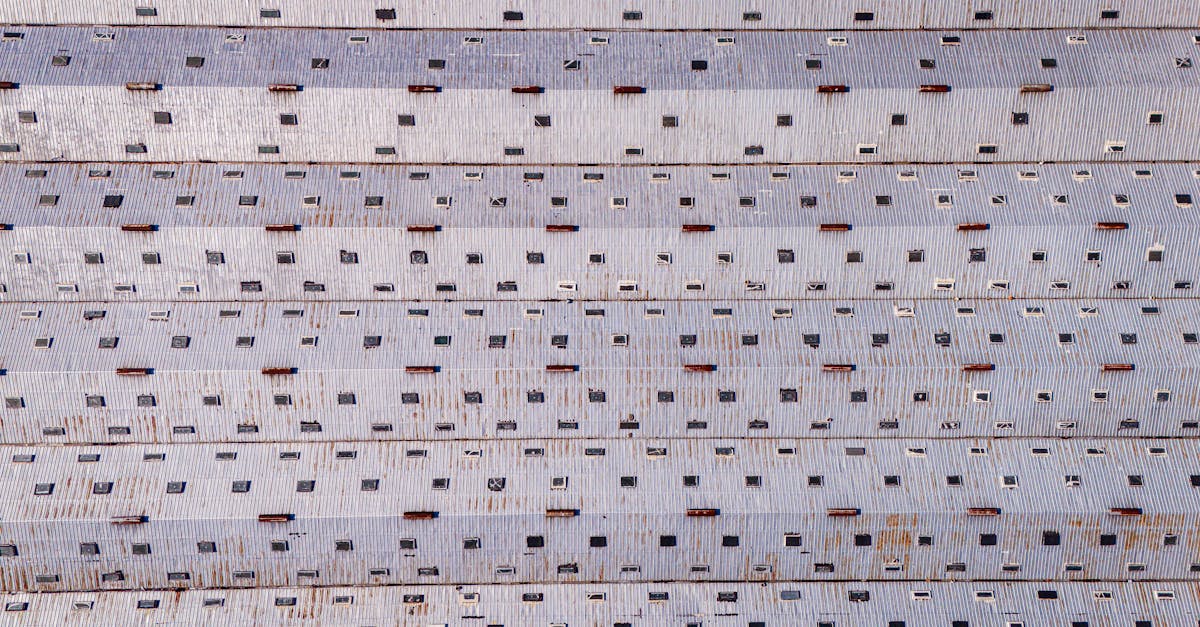

Regular cleaning is essential for maintaining the longevity and appearance of corrugated metal roofs. Debris such as leaves, twigs and dirt can accumulate over time, potentially leading to water pooling and rust formation. Implementing a routine cleaning schedule helps to prevent these issues. It is advisable to inspect the roof at least twice a year, particularly before and after the rainy season, to ensure any build-up is promptly addressed.

Using the right tools and cleaning agents makes a significant difference in the maintenance process. Soft-bristle brushes are effective for removing surface dirt without scratching the metal. Mild soap and water provide a gentle solution for most cleaning tasks, while specialised roof cleaning products can help tackle stubborn stains or rust spots. Ensuring that the gutters and downpipes are clear helps to facilitate proper drainage, further protecting the integrity of the roof.

Recommended Cleaning Solutions

For effective cleaning of corrugated metal roofs, a gentle detergent mixed with water serves as an excellent starting point. This solution can help remove dirt, grime, and other debris that accumulate over time. Using a soft-bristle brush enhances the cleaning process while preventing scratches or damage to the metal surface. Rinsing thoroughly with fresh water ensures that no soap residue remains, which could lead to additional build-up or corrosion.

For tougher stains such as rust or mildew, specialised cleaners formulated for metal surfaces can be applied. These products often contain ingredients that target specific issues without compromising the integrity of the roof. Always follow the manufacturer's instructions for application and dilution. It is crucial to conduct a spot test on a small, inconspicuous area first to ensure compatibility with the metal finish. Regular cleaning not only maintains the aesthetic appeal but also helps prolong the lifespan of the roof.

Assessing Structural Integrity

Regular assessment of structural integrity is vital for the longevity of corrugated metal roofs. Homeowners should conduct visual inspections to identify any noticeable changes in the roofing structure. Look for signs such as sagging or uneven surfaces. These indicators could signal underlying issues that might compromise the roof's performance.

In addition to visual checks, it is advisable to examine the connections between the roofing panels and the supporting framework. Any loose or rusted fasteners can lead to structural weaknesses over time. If such issues are detected, prompt action is necessary to ensure stability and prevent further deterioration. A specialist may be consulted for a comprehensive evaluation in cases of significant concerns.

Signs of Structural Damage

Identifying potential structural damage in a corrugated metal roof requires vigilance. Homeowners should regularly inspect the roof for visible signs such as sagging or uneven sections. Rust spots or corrosion can also indicate underlying issues that need attention. Be alert for leaks or water stains on interior ceilings and walls, as these may signal compromised structural integrity.

Physical damage from weather events presents another concern. After severe storms, check for displaced or missing panels. Cracks along the seams can weaken the overall structure, exacerbating water infiltration. Additional signs include loose fasteners or excessive movement in the roofing material when touched, all of which warrant prompt investigation.

FAQS

What are the common signs of condensation in roof spaces?

Common signs of condensation include water droplets forming on the underside of the roof, damp patches on the ceiling, and mould or mildew growth in the roof space.

Effective ventilation solutions include installing ridge vents, soffit vents, and gable vents, which help to allow air circulation and reduce moisture build-up.